Introduction

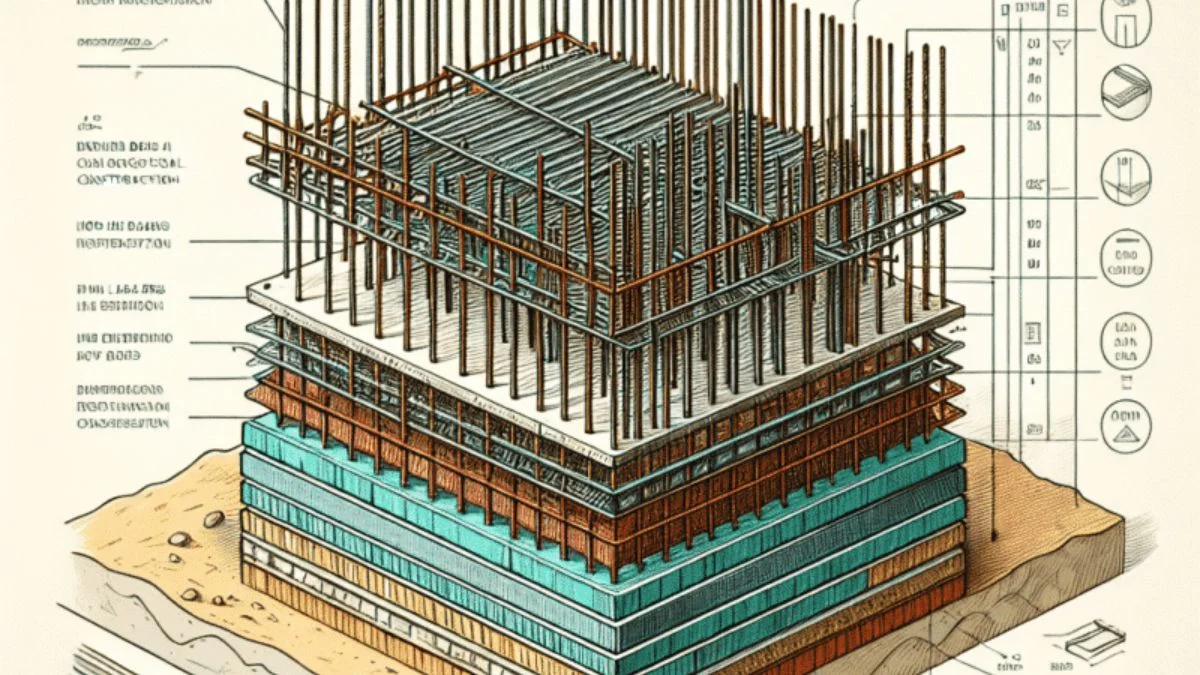

What is the Most Used Iron in Walls – When it involves constructing partitions, especially in residential and commercial buildings, the most commonly used iron is rebar or reinforcing bar. Rebar is normally crafted from metallic and is essential in presenting structural support to concrete partitions, enhancing their tensile power. It prevents cracking and facilitates stabilizing the integrity of the walls at some stage in events along with earthquakes and severe climates. In the United States, using rebar is standardized beneath the American Society for Testing and Materials (ASTM) pointers, ensuring compliance with safety and performance requirements. Understanding the function of rebar in wall production is essential for each developer and asset proprietor, as it immediately impacts the durability and longevity of any shape.

Types of Iron Used in Walls

1. Reinforcing Bar (Rebar)

Rebar is the most familiar iron used in wall creation, particularly in concrete structures. Typically composed of carbon metal, it affords the necessary energy to counteract tensile forces that concrete alone can not cope with. Rebar is to be had in diverse grades, sizes, and coatings to fulfill distinct production necessities. Its ribbed floor lets in for higher bonding with concrete, enhancing normal structural integrity.

2. Mild Steel

Mild metallic is another form of iron that is once in a while hired in wall structures, particularly for non-load-bearing programs. It is malleable and without problems doable, making it suitable for growing custom body systems and decorative elements. However, it is not as effective as rebar in providing tensile strength, limiting its utilization in structural applications.

3. Wire Mesh

Wire mesh, often crafted from welded or woven steel wires, is regularly used to enhance partitions and slabs in residential and commercial homes. It offers a surface for concrete to bond with and facilitates distribution loads across a much wider location. While no longer a substitute for rebar in essential structural applications, it serves as a cheap reinforcement approach in conditions in which decreased tensile energy is required.

Properties of Rebar

Corrosion Resistance

The longevity of a concrete structure heavily is predicated on the corrosion resistance of rebar. Epoxy-coated rebar and chrome steel rebar are available alternatives that enhance resistance to environmental elements, making them suitable for use in regions susceptible to moisture, salt, or chemicals.

Load-Bearing Capacity

The load-bearing potential of rebar is measured in phrases of yield electricity, with not unusual grades starting from 40,000 psi to over 75,000 psi. Choosing the appropriate grade is critical for making sure that walls can deliver the imposed masses without failure.

Installation Considerations

Spacing and Placement

Proper spacing and location of rebar are critical to maximizing its effectiveness in wall creation. Typically, rebar has to be positioned by nearby building codes and engineering calculations. It is often located vertically and horizontally in the concrete to form a grid, effectively resisting tension and shear forces.

Concrete Cover

Concrete cowl refers back to the layer of concrete that surrounds the rebar. An adequate cowl is important to protect the steel from corrosion and to prevent concrete spalling. Building codes generally specify minimal cowl requirements depending on the exposure conditions.

Best Practices for Using Rebar

1. Correct Sizing

Choose the proper size and grade of rebar for the specific application in keeping with the structural layout requirements. Consulting with a structural engineer can ensure compliance with protection standards and performance expectations.

2. Quality Assurance

Utilizing wonderful rebar is vital. Ensure the iron is sourced from reliable providers who adhere to enterprise standards and specs mentioned with the aid of ASTM.

3. Proper Handling

Handle and keep rebar efficaciously to prevent harm or deformation. Keep it dry and loose from rust before software, making sure it performs to its optimum capability.

Conclusion

The most commonly used iron in wall production is rebar, which correctly complements the structural integrity of concrete structures. Understanding the types, homes, and first-rate practices related to rebar is vital for developers and house owners alike, making ensure the sturdiness and safety of partitions in their homes.

FAQs about What is the Most used Iron in Walls

What is rebar?

A rebar, or reinforcing bar, is a metallic bar used to reinforce concrete and is critical for keeping the structural integrity of partitions and different concrete structures.

How does rebar enhance wall energy?

Rebar improves wall power by imparting tensile reinforcement that concrete lacks. It helps in lightly dispensing loads and preventing cracks or screw-ups underneath strain.

What are the one of a kind grades of rebar available?

Rebar comes in various grades, typically starting from Grade 40 to Grade 75, which refers to the yield electricity of the metal. Higher grades offer greater tensile energy and are used for extra-worrying structures.

Are there alternatives to rebar in wall production?

While rebar is the most commonplace reinforcement, options like fiber reinforcement, cord mesh, and composite materials may be used depending on specific mission requirements and conditions.

How do I realize the proper size of rebar for my wall?

Choosing the proper length of rebar entails consulting with a structural engineer or adhering to neighborhood building codes and requirements primarily based on the walls peak, load, and exposure conditions.